What is Thermal Spray

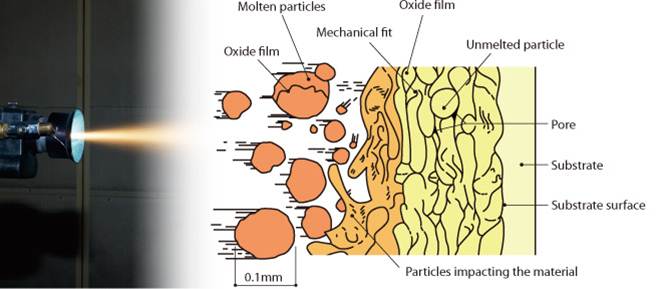

- Thermal spray is a coating process in which melted wire or powder materials are sprayed onto the surface of the work piece.

- Thermal spray coatings not only repair damaged surfaces, but can replace worn surfaces with a stronger, better-wearing finish that can keep your equipment running better, longer.

- Thermal spray can also extend the life of your NEW parts by coating them prior to putting them into service – this will maximize your investment in new parts for your process.

Benefits of Thermal Spray

- Reduced Cost– Instead of making the entire part out of an expensive material, a high-performance material is sprayed onto a low-cost base material.

- Low Heat Input– Thermal-sprayed coatings do not impact the substrates’ microstructure. The coating does not penetrate the base material, i.e., there is no heat-affected zone.

- Versatility– Almost any metal can be sprayed.

- Thickness Range– Can build up from 0.001″ to more than 1″ thickness, depending on the coating sprayed.– Coating thicknesses generally range from 0.001″ to 0.100″.

- Processing Speed– Spray rates range from 3 to 60 lb/h depending on the material and the spray system.

Other benefits include:

- Thermal Spray is a mature process dating back to the early 1900’s – with proven results

- Application Specific – Engineered Coating

- Superior Wear Resistance

- Excellent Corrosion resistance

- Dimensional restoration

- Excellent Bond Strength

- Provide textured surfaces for traction/grip

- Heavy Build-ups More Quickly

- Minimal heat build-up in base metal (<300°F)

Types of Thermal Spray

Click below to view a description of the different types of Thermal Spray

High Velocity Oxygen Fueled (HVOF)

Twin Wire Arc Spray (TWAS)

HVOF Videos

TWAS Videos